Solar Success Story

ExtraPower: a detailed case study of a complex PV rooftop project for Deceuninck.

The Project

Deceuninck

Deceuninck decided to evaluate their current and future uses of energy resources.

After this, the team decided to set an ambitious goal to become fully energy self-sufficient.

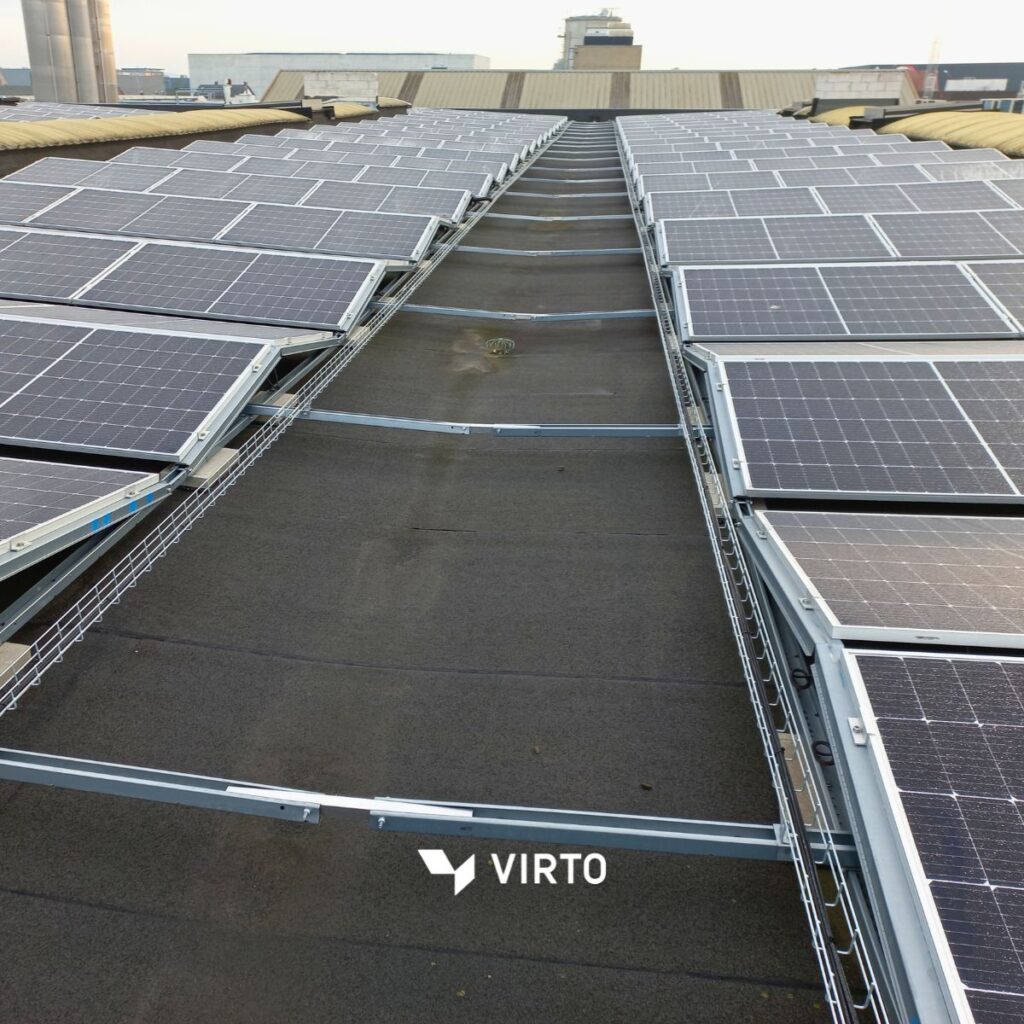

In order to meet their energy needs, the company would make use of as much locally produced green energy as possible. They set out to produce solar energy by placing a large-scale solar rooftop installation on its warehouse in Hooglede.

ExtraPower

ExtraPower”, a Belgium company focusing on engineering, installing and maintaining commercial and industrial solar parks, was selected for this project.

Offering a complete package of advice, design, execution and follow-up for both small and large projects – however complex they may be.

Technical info

- Virto.CAD software

- Location: Deceuninck, Hooglede, Belgium

- Power (DC): 3 MWp // 852 tons of co2

- Solar module type: 7036 x Longi LR5-54HPH-405M (405Wp); 390 x Trina TSM-DE19-545 (545Wp)

- Number of solar modules: 7426 modules

- Inverters used: NOB1: 9x Huawei SUN2000-100KTL-M1; NOB2: 9x Huawei SUN2000-100KTL-M1; NOB3: 1x Huawei SUN2000-100KTL-M1; NOB4: 1x Huawei SUN2000-100KTL-M1

- Start: 9 May 2023

- Lead time DC: 10 weeks

- Integration: 1 Augustus 2023

- Inspection: 28 August 2023

- Commissioning: 15 September 2023

Tasks

- Design

- Engineering

- Purchasing all materials needed for this project

- Placing all modules and inverters

- Placing and connecting all 4 grid connection cabinets

- Cabling

- Commissioning

- Communication with network operator and arranging inspection

- Providing “telecontrole” monitoring, issued by network operator Fluvius

Challenges

Large-scale solar installations may be more complex than smaller ones. The ExtraPower team encountered a few challenges in the design process of the “Deceuninck” project.

Multiple rooftops

In the last couple of years, the Deceuninck site has known some major changes. Because of the business’s growth, a large number of warehouses have been added throughout the years. As a result, the site now has multiple separate building – and thus, separate rooftops. Moreover, all rooftops have different sizes and slope angles.

Because of the number of rooftops, the different sizes and slope angles, it was of great importance to map each rooftop surface separately in the design.

Stability & Profiles

Given the number of rooftops, it was extremely important to use special substructures in this PV projects.

In addition, the customer’s insurer also imposed provisions in the stability study on the one hand and some additional requirements that the structures had to meet, on the other hand.

Therefore, ExtraPower decided to collaborate with a third party: SADEF. Voestalpine Sadef is specialised in supplying custom-made steel profiles and offers high-quality solutions for innovative substructures. Moreover, Sadef distinguishes itself by offering customization and extensive detailed engineering services

As a “profile solutions provider” and a detailed engineering, Sadef succeeded in providing custom-made profiles for this project. These profiles were made in such a way so they would meet the provisions and requirements that were set out by the insurance company in the stability case study.

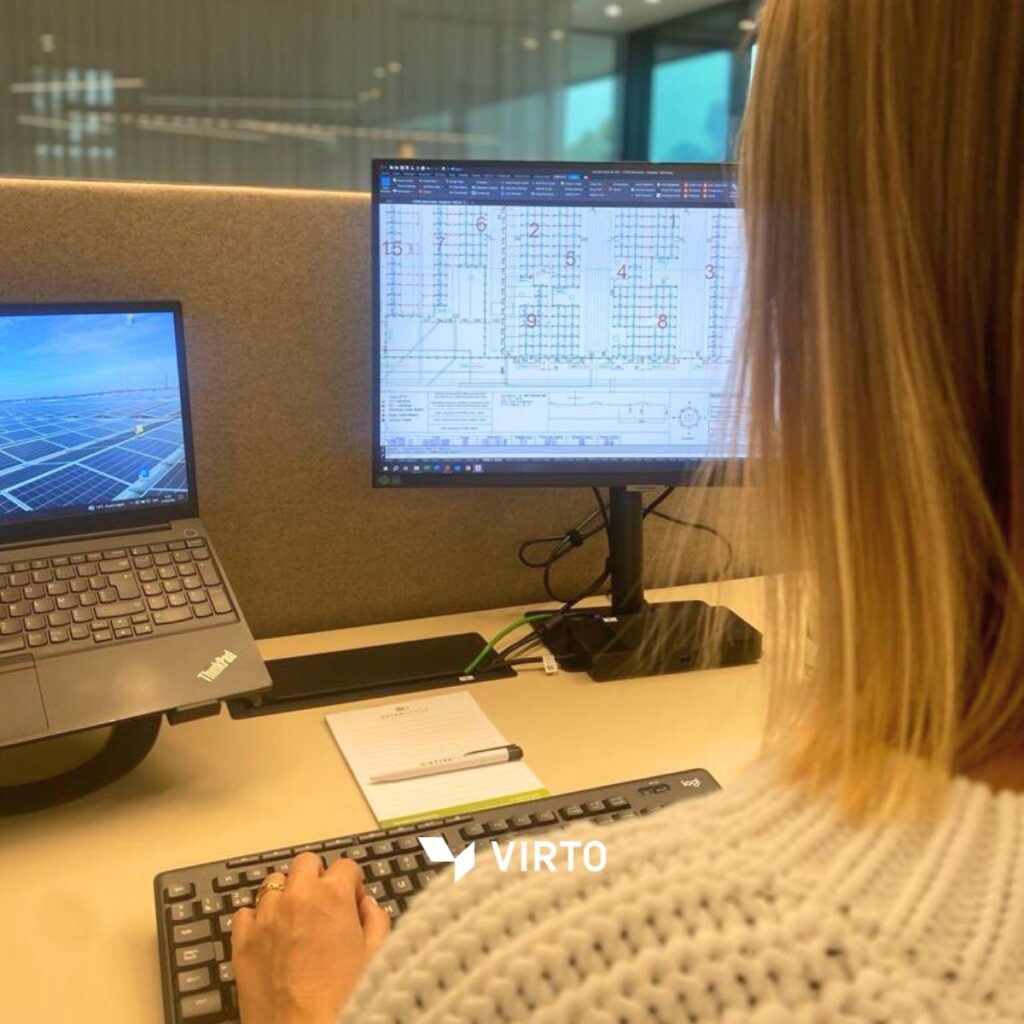

Next, it was up to ExtraPower again to upload the entire engineering into construction plans which will be used to draw a CAD design in Virto.CAD.

Cable lengths & connectors

The complexity of the rooftops also created a challenge with regards to DC cable lengths and connectors.

Given the total surface of the rooftop, one had to use very long DC cables.

In order to have a clear overview of the number of DC cables, the total length and the number of connectors, ExtraPower used Virto.CAD PV design software to map and export all this information.

“We have been able to engineer and install a very complex solar installations with an accurate string design, DC cable calculations and shadow analysis”, confirms ExtraPower. “As a result, we have succeeding in building a solar installation with maximal solar yield. Not only did we manage to finish the project on time and within the planned schedule, but also have a happy customer in the end”. – EXTRAPOWER

Solutions

ExtraPower used Virto.CAD, our powerful PV plugin for CAD programs such as AutoCAD, to bring this project alive.

Virto.CAD speeds up the entire design and engineering process of commercial and industrial PV rooftop installations and PV ground-mounted projects. By automating repetitive tasks and calculations – such as module placement – engineers are able to save more than 75% on engineering time and costs. As a result, they can spend more time on experimenting and finding creative solutions.

Many Virto.CAD features assisted ExtraPower during the design and engineering process, as follows:

Uploading imagery

First, ExtraPower uploaded photos and drone images of the projects into Virto.CAD and use these as the basis to start the drawing.

Next, the team made a CAD drawing of the entire project.

Detailed String Design

As previously mentioned, the different rooftops all had different sizes, slope angles and orientations. Therefore it was crucial to group certain rooftops in an intelligent way in a string design. By doing so, it would be possible to map everything clearly to guarantee the best yield possible.

ExtraPower used Virto.CAD to map everything in a string design. “By using the group-functionality in the systems configurations, it was possible to draw all strings without any errors. This way we were able to simplify and speed up our engineering process. As a result, we saved time and costs”, says ExtraPower.

Analyse shadows based on irradiance

To guarantee maximal solar yield, one used Virto.CAD’s feature to analyse shadows based on irradiance while taking surrounding obstacles into account.

For instance, a large number of silos can be found near the warehouse buildings. Given the height and width, these silos could create shadows on the solar modules.

For this reason, ExtraPower mapped all silos into Virto.CAD and simulated the shadows based on irradiance. Based on this data, the engineers were able to optimize the solar module layout to make sure the solar yield would be maximal.

Identify cable lengths

“Thanks to Virto.CAD we were able to accurately calculate and successfully export the amount of DC cables and the total length needed for this project. In addition, the software allowed us to calculate the voltage drops”, concludes ExtraPower. “Moreover, we accurately determined the number of connectors we needed to connect the strings and jumpers”.

Results

By using Virto.CAD software, ExtraPower experienced the following benefits:

The option to map and draw multiple roofs in one project.

Save time and costs. Repetitive tasks and calculations are now automated, such as automated solar module placement on all rooftops.

Generate a detailed engineering: calculate cable lengths, simulate shadow based on irradiance, and more.

Simplify and visualize a complex string design without any errors.