Advantages of Cable Tray Management for PV projects

One knows the common saying “Better safe than sorry”, and it couldn’t be more applicable to designing large-scale solar parks. A very important – yet often underestimated – part of the design process of solar rooftop projects, is “Cable Tray Management”.

Taking defining and important decisions and implementations in the design phase, will pay off later in the execution phase. These early decisions could prevent errors or issues which may delay the construction of a solar park, for instance. For this reason, we look into the advantages of cable tray management for solar PV projects.

What is cable tray management?

When it comes to designing and engineering large scale solar parks, not only materials such as solar panels and mounting systems are needed, but also cables and cable trays.

Cable tray management comprises the number of cables and cable trays and how to effectively manage and distribute these materials in a solar project.

Applications in the design phase

It is crucial to map out the number of cables and cable trays in the early design phase of a solar project. In doing so, engineers can spot potential issues, situations or errors before they may affect the continuation, budget and time frame of the project. For instance, some errors may delay the construction phase or even increase the budget of a solar project.

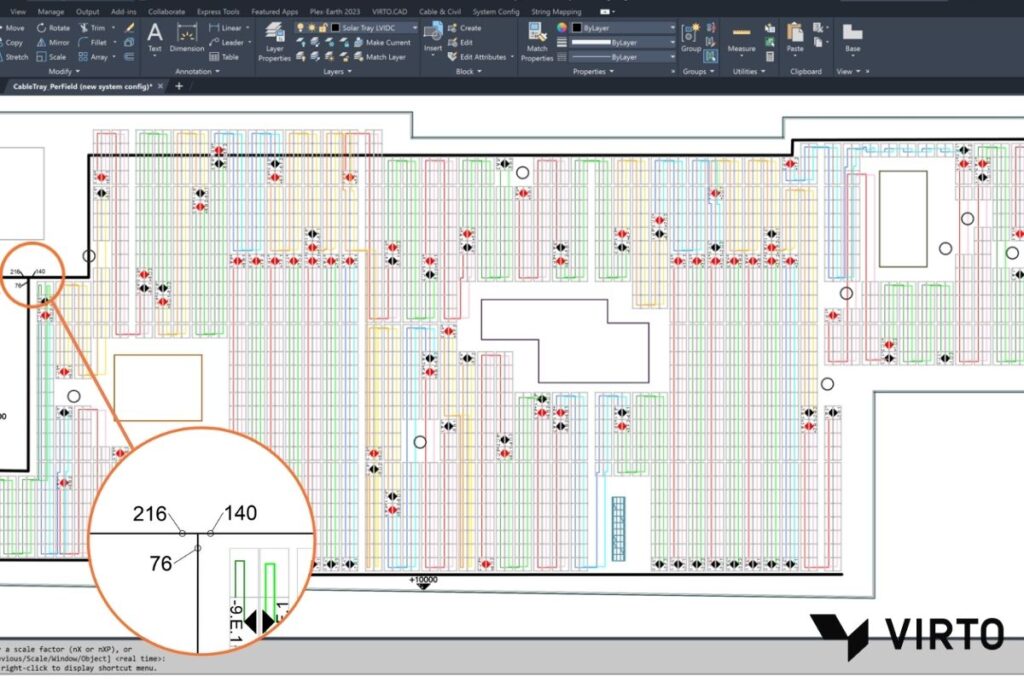

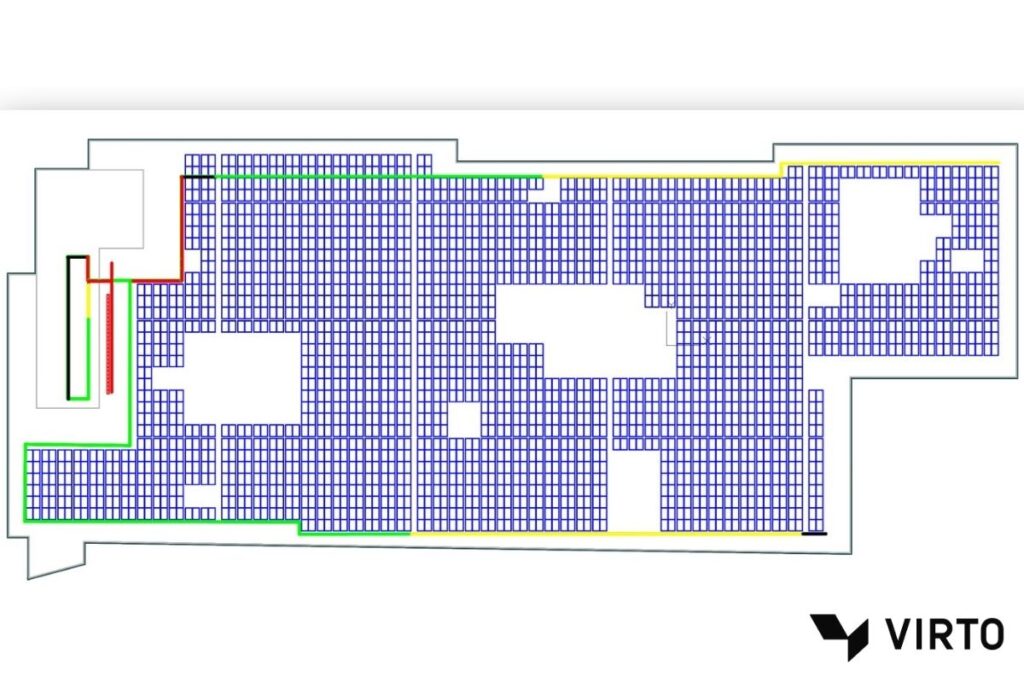

Cable tray management in the design phase of a photovoltaic rooftop project comprises defining the path from solar panels to the invertors. This path will be used as a “route” for the cables and cable trays. By mapping out this path in the design phase, engineers can choose the most efficient route. This leads to lower losses in both space and materials.

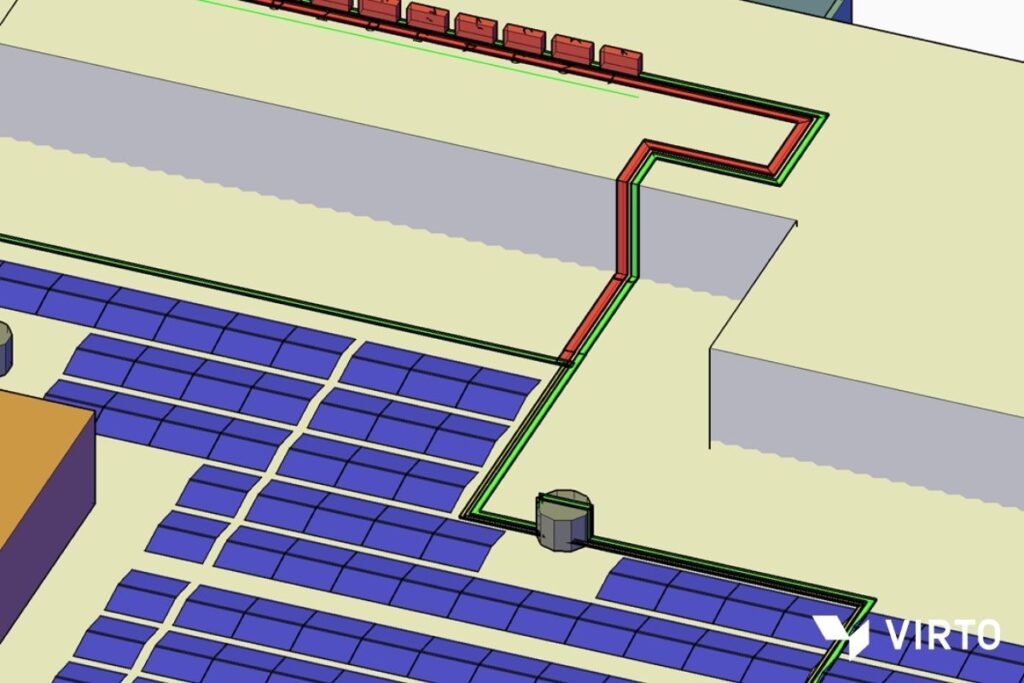

Secondly, it is recommended to use different types of cables and cable trays to work cost efficiently. By implementing different sizes of cable trays into the projects, the more flexibility in choosing the right sizes exists. This leads to a lower number of overfull or (almost) empty cable trays. The maximal full ratio helps to determine what size is applicable in which situation.

Another aspect from cable tray management, is the “rooftop ballast”. Cables and cable trays add weight to the rooftop. To avoid too much weight on a specific area of the rooftop, engineers can choose to spread out the cables and cables trays. This way the weight will also be spread out over several areas on the rooftop.

Lastly: plus and minus polarities need to be separated. In case the DC cables are damaged, “solar fires” (arcs) can occur. It is therefore very important to leave enough space between the plus and minus polarities.

Common rooftop issues and errors

Without applying effective cable tray management in de design phase, the following issues and errors may arise later in the execution phase:

- Insufficient space for cables and cable trays. For instance, solar modules are placed in such a way they are too close to the rooftop edging. Because of this, there may be no space left for cables and cable trays next to the installation.

- Unknown length or width.

- No “filling ratio”. A filling ratio makes sures that all cable trays are filled in the most efficient way. If this ratio has not been applied to the solar project, it is possible that some cable trays are either too full or to0 empty. This leads to efficiency losses and more expensive materials.

- Insufficient support for cable trays which may cause them to bend on the heaviest point. This may then lead to damage.

- Wrong cable and cable tray calculations resulting in length errors.

Cable Tray Management in PV Design Software

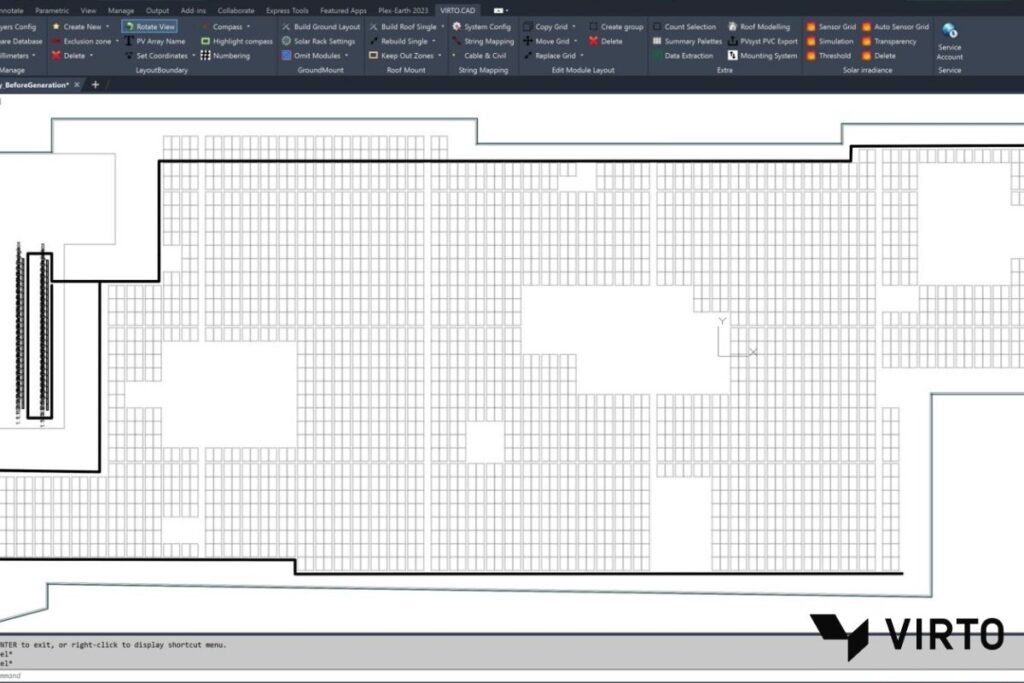

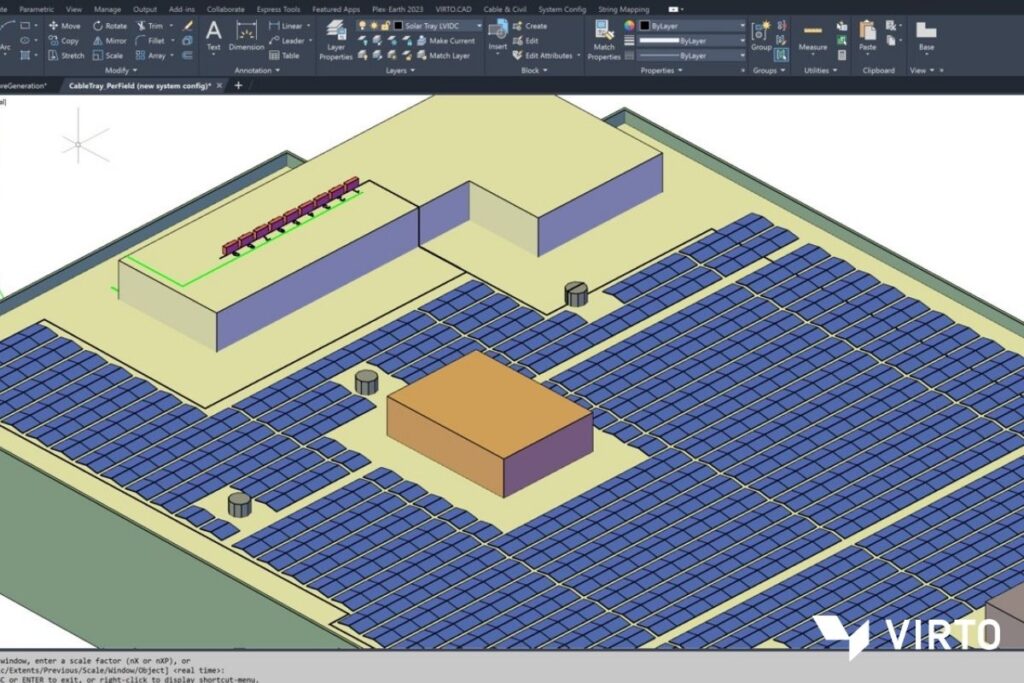

The potential errors and issues mentioned above, can be prevented and solved by using PV design software. Virto.CAD, our plugin for AutoCAD and BricsCAD, supports and boosts the design process of large-scale solar parks by automating module layouts, calculations, bill of materials and more. Because of this automation, engineers no longer need to calculate or draw manually leading to fewer mistakes or issues.

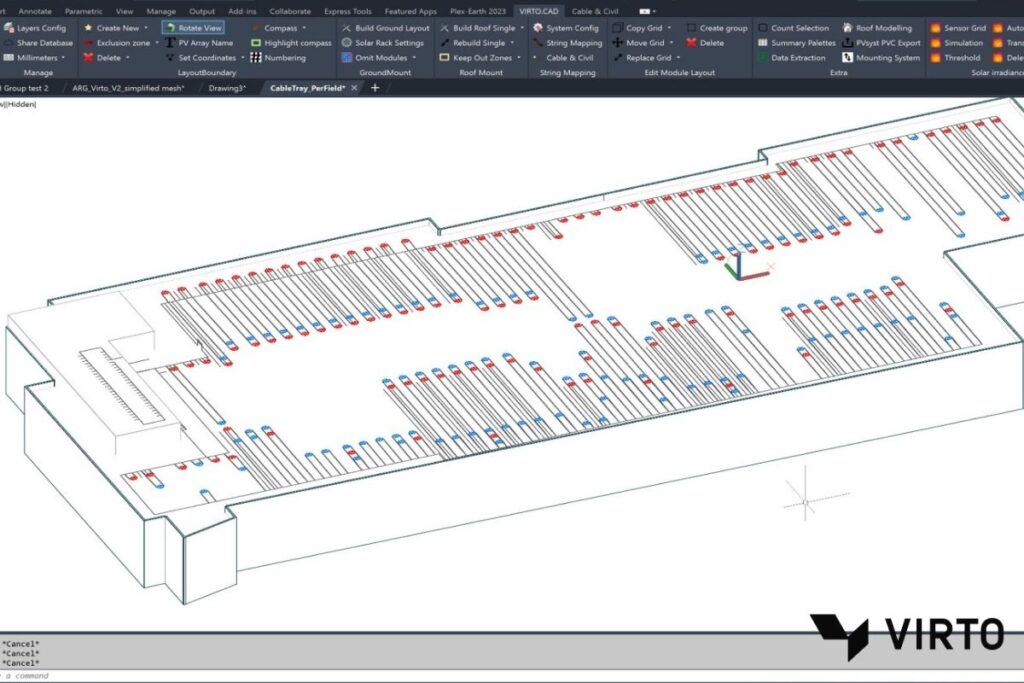

Virto.CAD has clear cable tray path and routing options. For instance, you can choose to define cable tray paths on and off your roof surface or even bridge between buildings. Secondly, you can opt to place inverters or combiner boxes in or outside your building. Finally route all your AC and DC cable in 3D through the shortest path to each device.

Virto.CAD allows to automate the following tasks:

Draw Cable Routing

Because of these features, engineers can look at strategic rooftop positions and take these into account for the cable tray paths and routings. Additionally, one can shorten the cable lengths in the solar project.

Automatic Cable Routing

Calculate all string lengths automatically on the one hand; visualize according to a predefined route on the other hand.

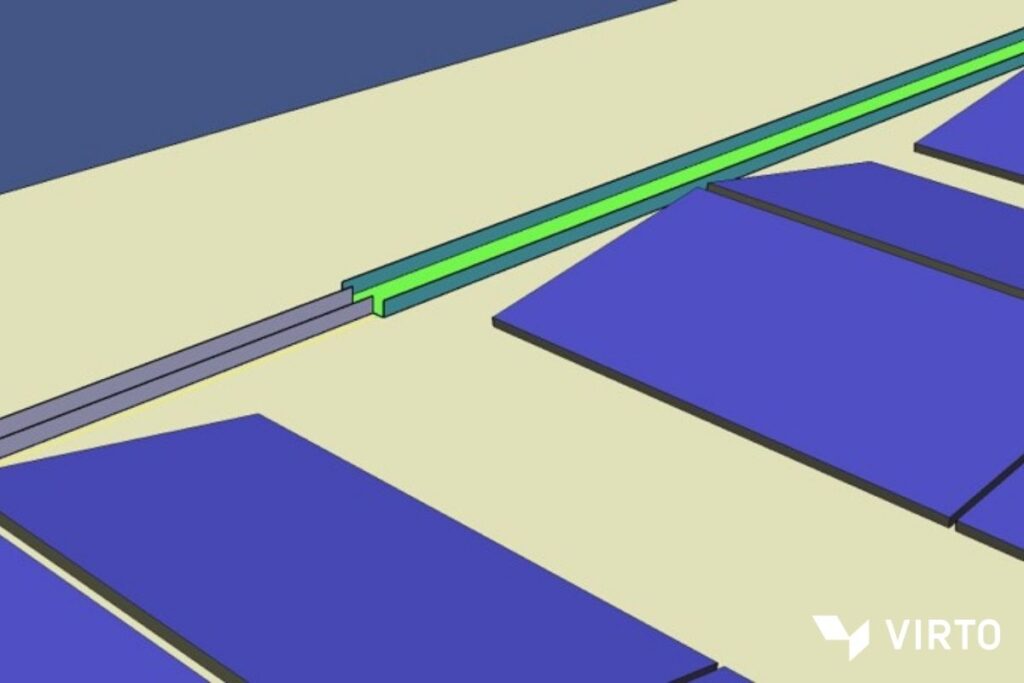

The result is the number of cables per cable routing. Here’s an example of a T-point calculation.

Height differences in cable routing

Virto.CAD will detect height differences, roof edges and obstacles automatically.

Automatic cable tray placement

Virto.CAD will detect height differences, roof edges and obstacles automatically.

3D visualisation of the cable trays

Our PV design software visualizes all cable trays on the drawing, including length and height dimensions.

Next, the exact number of cable trays and cable lengths is automatically calculated in the Bill of Materials.

“Cable tray placement” will be available in our next Virto.CAD Release, version 1.11.

Conclusion

Cable Tray Management is a crucial part of the design process of a solar rooftop project. Defining cables, cable tray paths and routing in the early phase will prevent a lot of potential issues or errors in the execution phase. By using Virto.CAD software to automate the entire solar engineering process, engineers can map out module layouts, cables and cable paths and routings. As a result, the execution and construction phase will not be delayed.

Try Virto.CAD for free for 30 days (request here)

and experience all its features and functionalities. Our support team can assist you too.

Schedule a free 90-minute demonstration

in which our customer success team will introduce you to our solar design software.

Get In Touch

Request a free trial, schedule a demo, give us your feedback or ask us anything!

Simply drop us an email or give us a call.

Our team will be happy to assist you.